Tooling Combinations

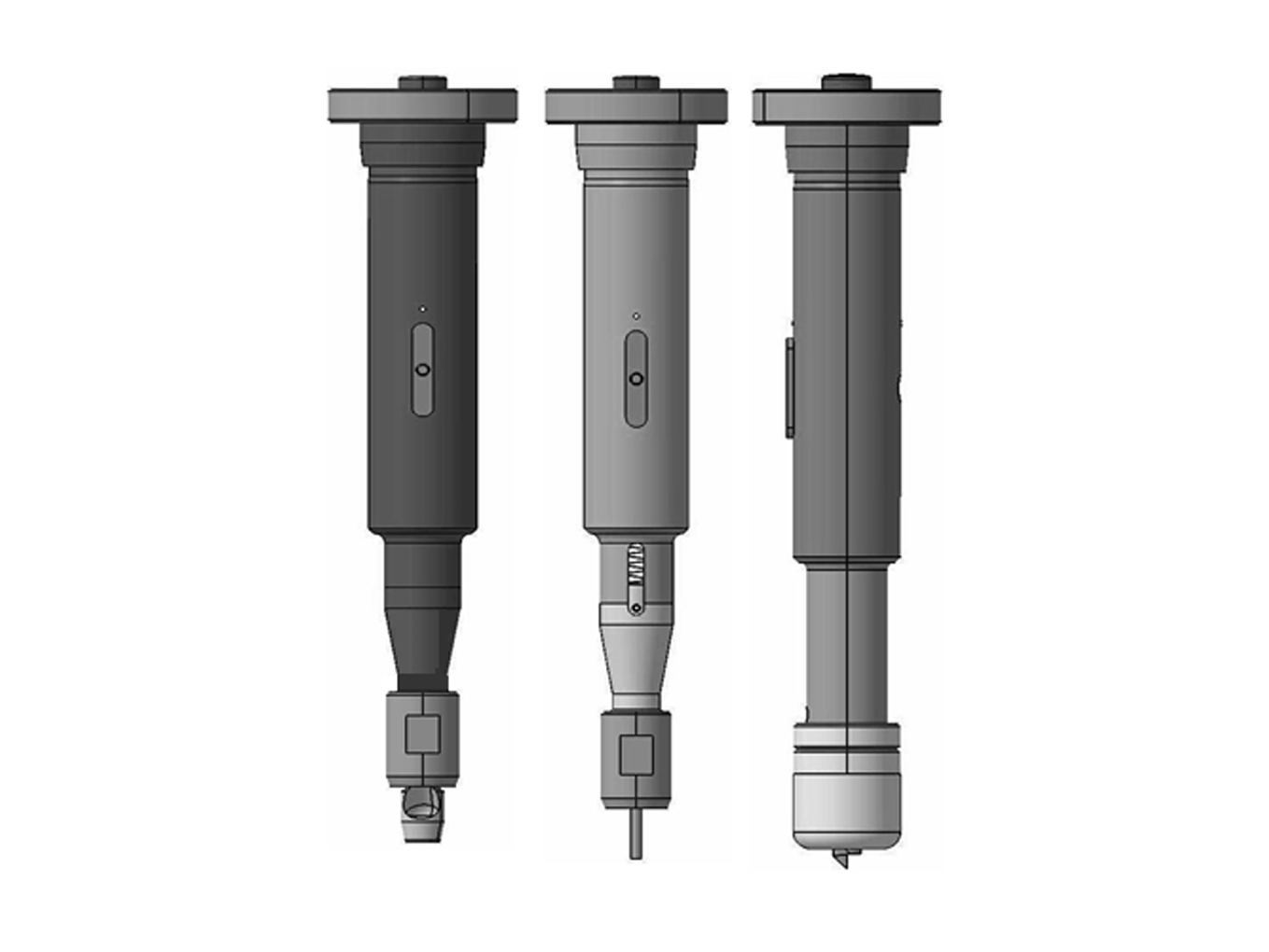

Drag Knife Chuck

The Drag Knife Chuck (DKC) is ideal for total cutting rigid materials like thin compressed non-asbestos, laminates & plastics up to 6mm (1/4”) in thickness. The use of drag knives allows for maximum processing speeds, and compared to a pneumatic or electric driven tool, the DKC is very inexpensive to purchase & maintain. The micro-metric adjustment knob & glide-boot allow for cutting set depths & intricate details.

Kiss Cutting Drag Chuck

The Kiss Cutting Drag Knife Chuck (KDC) is commonly used for the total cutting, kiss cutting or a combination of both when processing various laminated materials including vinyls, pressure sensitive tapes, foam tapes, films, and similar substrates. The KDC performs clean, precise cuts without damage to the liner & very high processing speeds.

Electric Oscillating Chuck

The Electric Oscillating Knife Chuck (EOK), is ideal for cutting softer, low-medium density materials like thin foams, soft rubber, pure graphite, leather, laminates, adhesives and similar products. The high oscillating frequency, available from 35-100-200 Watts, makes it possible to cut @ higher processing speeds and increased throughput. The EOK is available with a 0.8-1.0mm stroke, which also makes ideal for kiss cutting soft laminated materials or detailed geometries.

Pneumatic Oscillating Chuck

The Pneumatic Oscillating Chuck (POC), is an air driven tool engineered for cutting the most difficult materials but is also used for cutting thick, soft substrates as well. The considerable air pressure required (130-135 PSI), along with a 6mm stroke, grants this tool the power required for the toughest materials including steel inserted graphite, compressed non-asbestos, ¾” rubber, dense foams, Teflon, felts, multi-layer fabrics (1” thickness), plastics and similar substrates. Three versions of the POC are available, accepting blades with a thickness of 0.64mm, 1.0mm & 1.5mm. On the FLEX HD Series, materials up to 130mm (5.1”) thick can be processed when utilizing the 1.5mm POC.

Powered Rotary Chuck

The Powered Rotary Chuck (PRC), is designed for cutting difficult fibrous materials, both uni-lateral & bi-lateral weaves, at a high rate of speed. The PRC is suitable for processing carbon fibers, Kevlar, fiber-glass, aramid and technical textiles & composites in general. A wide variety of blades are available, circular, 4, 6, 8 & 10 sided configurations for cutting the widest range of materials with exceptional performance & low operating costs.

Pneumatic Milling Chuck

The pneumatic milling chuck, or PMC, was designed for companies that want the flexibility for light-duty milling applications for rigid materials, primarily plastics (ABS, UHMW, PP, PE etc..), that are not capable of being cut with the traditional pneumatic oscillating knife chuck. The PMC accepts a wide range of end mill bits with a 6mm collet, with the rotational speed fixed @ 15,000 RPM, and can be fitted into any of the traditional modular heads.

Creaser & 45° Angle Chuck

The creaser chuck is ideal for processing a wide range of single, double & triple wall corrugated cardboard. This chuck accommodates creaser wheels with a diameter of 40mm, 70mm and 95mm. Fully supported by the machines operating software, and with adjustable pressure settings, the creaser chuck produces high-quality creases without tearing or cracking the top layer of the corrugated material. To further add to the flexibility of this tool, the creaser wheel attachment can be removed, and a 45° angle knife can be added for producing complex designs from foamcore, corrugated, rigid foams and similar materials.

Auxiliary Tools

Side auxiliary tools can include rotating punches/drilling stations, kiss cut tool, creaser wheel for carton stock or thin plastics, or a 45° angle knife. Only available on the 5-Tool or 7-Tool modular head.

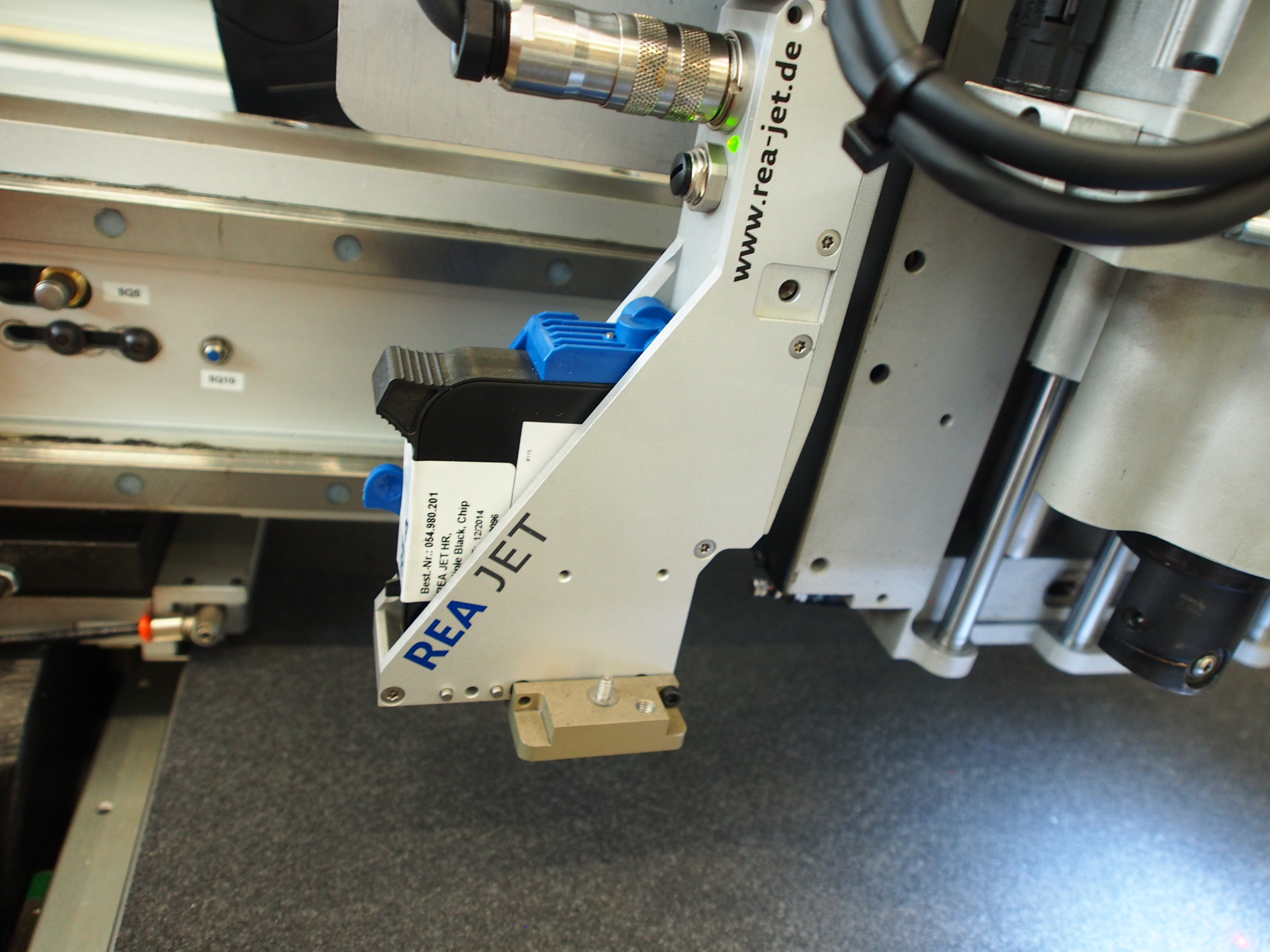

Ink-Jet Printer

REA-JET Thermal Ink Jet Printer Module: The high resolution ink jet printer used on all TWINS models utilizes thermal ink jet technology that is used & trusted by millions of users. The robust stainless steel housing, intuitive operation & well-conceived print head design makes this coding & marking system suitable for unlimited industrial applications.

Camera System

Repositioning for printed materials (fiducial points recognition)